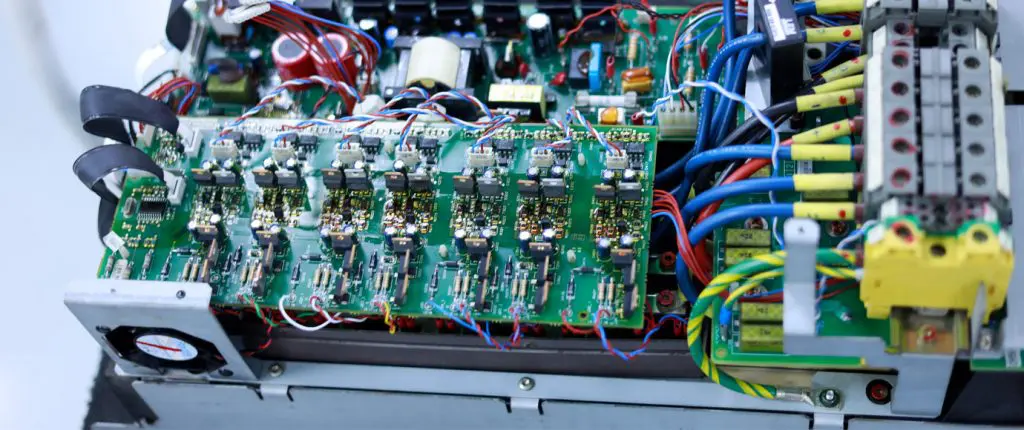

When buying a VFD, the first thing you should keep in mind is to maintain it clean, cold, and dry. These three suggestions will significantly increase the lifespan of your VFD. Unfortunately, your VFD will have issues at some point in the future (hopefully many years down the road). In order to keep your equipment in peak condition, this article will discuss some of the most typical causes of VFD problems and failures and offer some advice on how to avoid them.

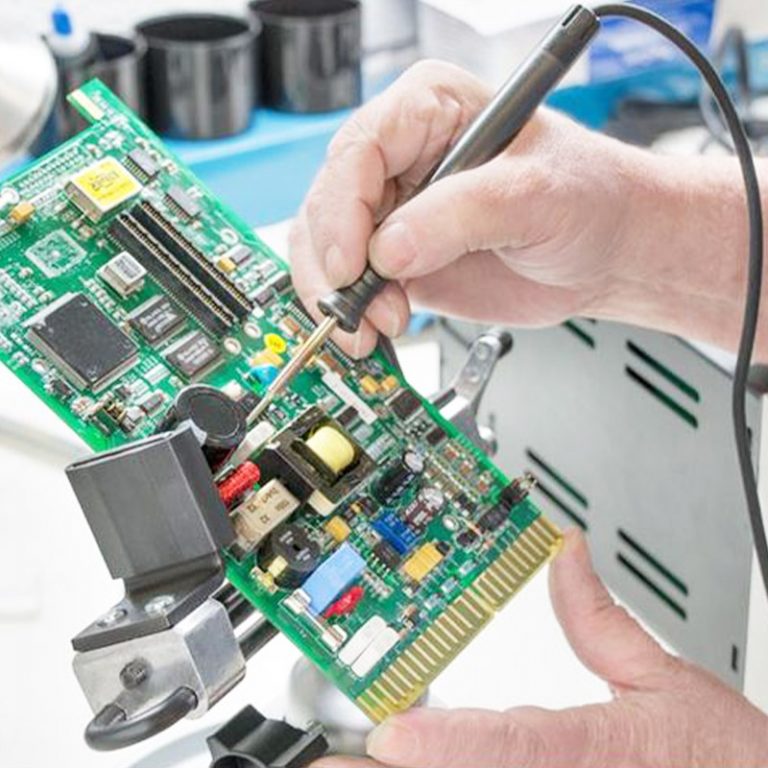

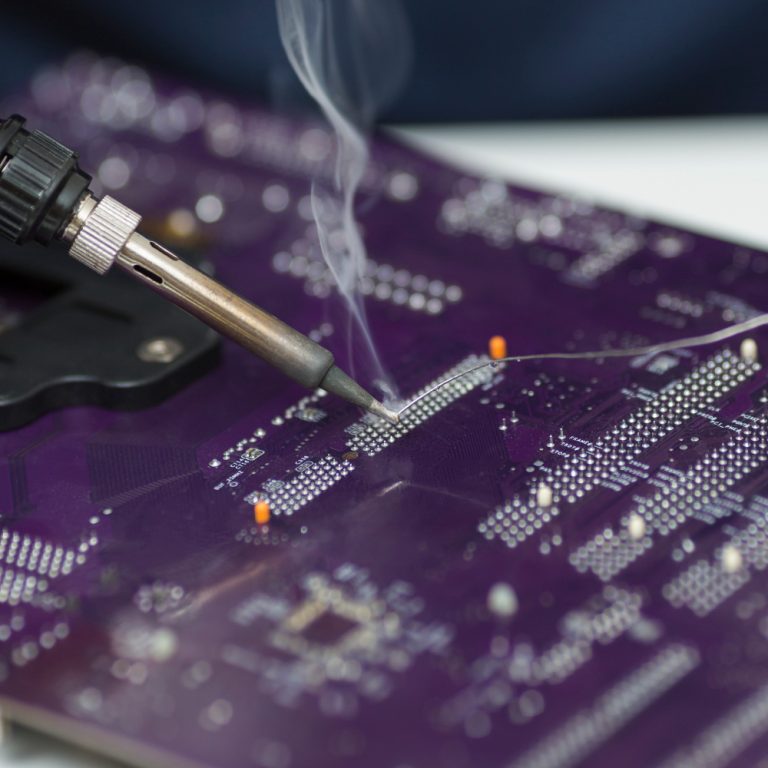

1.Defective Connections

Loose connections or aging components may be at blame if your VFD doesn’t seem to be performing as well as it once did. The two main factors causing weak connections and rapid aging of some components are high levels of vibration and heat production. The circuitry may then experience hazardous electrical arcing as a result. Arcing can harm other components of your equipment and put your technicians or staff at risk while operating. If loose connections are not fixed right away, they could permanently harm your equipment.

Excessive heat can also be brought on by loose connections or current levels beyond the drives’ rated level, which is typically the result of contaminant buildup.

Using a temperature probe or portable digital pyrometer may be necessary to diagnose a loose connection if visual inspection of the connections is insufficient. A loose connection is indicated when a connection becomes hotter than the wires it is connected to. Blown capacitors, short circuits, and excessive component wear are all effects of overheating.

2.Unhealthy Environment

VFDs are constructed similarly to computers, and computers are quite vulnerable to dirt, moisture, overheating, and dust. A VFD’s operational life will be limited if it is used in a location that is frequently exposed to dust, debris, or moisture.

Your VFD is susceptible to circuit board corrosion in high humidity situations, such as wastewater treatment facilities, because moisture is continuously drawn into the cabinet through the cooling vents. This, combined with potential infrequent use, can allow moisture to accumulate without giving it enough time to be dried out by heat and airflow.

Make sure your VFD’s operating environment and storage area are clean and dry to prevent problems brought on by humidity. You may also want to think about using a dehumidifier to dry up the air (ensure the dehumidifier does not leak near any electronic equipment). A NEMA 4, 4X, or 5 enclosure may be required for locations with high humidity or washdowns.

The obstruction of cooling vents by airborne particles is another frequent environmental factor that leads to VFD failure, particularly when moisture or oil is present. Your VFD circuit boards may also become shorted out by metallic particles. Circuit board traces or components with tracking or arcing signs are indicators of contamination failure.

Clean all components of your VFD at least once a month to prevent adverse side effects or potential catastrophic failure caused by buildup. Additionally, confirm that you are utilizing the appropriate cabinet for your setting. For cooling airflow, some cabinets incorporate side vents, however these are more susceptible to contamination. If necessary, drives can be purchased in sealed, dust-free housing. Always keep your VFDs free from moisture, dust, and other contaminants.

3.Overuse of equipment

VFD failure can be facilitated by intentionally exceeding the manufacturer’s advised operating limits or by doing so unintentionally. Any component’s lifespan is shortened and eventually fails when used at a greater rating than its safe operating limit. Verify that all inverters are being used in accordance with the manufacturer’s instructions to prevent problems caused by overuse.

4.Faulty equipment

Unfortunately, it’s possible that the wrong VFD will be suggested for your machinery. Performance will inevitably suffer if you unintentionally connect your VFD to an incompatible motor or equipment. Prior to connecting your VFD to the device, always make sure to double- and triple-check the compatibility of your motors and equipment.

5.Unsafe Current

This is another frequent issue that is typically brought on by excessive acceleration at startup. Check all power connections to make sure they are securely connected in order to rule out an overcurrent fault. Overvoltage or overcurrent, blown fuses, and inevitably VFD damage are all consequences of loose power connections. Drive performance can become unpredictable due to loose wiring. This may lead to unpredictably fluctuating speeds and a loss of VFD control.

Use the auto tuning option to assist prevent overcurrent fault (if your VFD offers it). The drive can recognize the connected motor thanks to this function. This enables the use of rotor information in processor algorithms for more precise control.

Checking the mechanical load for worn or broken parts, high friction, or other issues is the second method for preventing overcurrent faults. If necessary, fix or replace any worn-out or damaged components.

Checking the input voltage and acceleration rate is the final option. Overcurrent faults may occur if the incoming voltage is too low or the acceleration rate is set too quickly. To fix the problem, stabilize the input voltage and acceleration rate.

6.High Bus Error

This is a typical mistake that is brought on by outside circumstances. A high bus failure is typically caused by an instantaneous voltage spike in the ac line or a “overhauling load” brought on by the machine’s inertia. When the load continues to rotate more quickly than the motor’s prescribed speed, this occurs. Typically, the VFD trips on a high bus to protect itself when this occurs.

Check the power supply for consistency and adapt the deceleration time to the load if your VFD displays a high bus fault. Dynamic braking or a regenerative power control circuit may be included to help the VFD and prevent a high bus fault if the process calls for quick deceleration.

7.Charger Fault

Electrolytic capacitors experience electro-mechanical wear because of their short lifespan and accelerated aging compared to other components. This alone might contribute to inverter failure.

Additionally, capacitors are quite temperature sensitive. The life of the components will be shortened by operating temperatures beyond the manufacturer’s specifications, which are frequently brought on by excessive current. Higher temperatures cause electrolytes to evaporate more quickly. Capacitors’ lifespan lengthens when they’re routinely utilized at less than the prescribed rate.

8.Start-Load Current that is High

A high current or high load reading can be an indication of mechanical binding or of some sudden changes in the speed or load of the process. A VFD might get overloaded if pumps and fans run at speeds that are even a few revolutions per minute higher than usual.

Before turning them on, make it a point to verify every component that the VFD drives. Before starting up, conveyors must be cleansed of all loads; pumps must be free of ice and debris; and any load should not include moisture. Because wet material is heavier than dry material, it can unexpectedly load the VFD, overloading the motor or VFD.

Using a VFD with a longer acceleration rate is another option to alleviate a high starting load. This begins a load gradually and smoothly as opposed to jerkily. Because a VFD only draws 100–150% of the load, a slow, smooth start is less demanding on mechanical components and has reduced line requirements.

You should be ready to provide the answers to the following questions when assisting your VFD specialist with troubleshooting your VFD:

- Was there a reason why the machine jammed?

- At the time of breakdown, what was the machine driving?

- Are there power factor correction capacitors present on the property? If so, when will they change?

- Was there any welding or construction going on next to the VFD?

- Did the utility notice any alterations?

- Was there a brownout or a lightning-caused power shutdown?

- Did any other equipment trip simultaneously with the VFD?

- What was going on with the utilities?

If you are experiencing such issue switch your VFD, reach out our technician immediately to get it resolved easily. Being the best Electronics companies in Dubai Automat can provide top quality drive repair service.