Understanding PCB and CNC Controller Repair

Printed Circuit Boards (PCBs) and CNC (Computer Numerical Control) controllers are essential components in various industries, from electronics to manufacturing. When these components malfunction, it can lead to significant disruptions and financial losses. This blog post will delve into the intricacies of PCB and CNC controller repair, providing insights into common issues, repair processes, and preventive maintenance.

PCB Repair: Restoring Functionality

PCBs are the backbone of electronic devices, housing components and interconnecting them. When a PCB malfunctions, it can be due to several factors, including:

- Component failures: Transistors, capacitors, resistors, and integrated circuits can fail due to various reasons, such as aging, overheating, or manufacturing defects.

- Physical damage: PCBs can suffer from physical damage, including cracks, burns, or corrosion, often caused by accidents, exposure to harsh environments, or electrical surges.

- Manufacturing defects: In some cases, PCBs may have manufacturing defects, such as missing components, incorrect solder joints, or faulty traces.

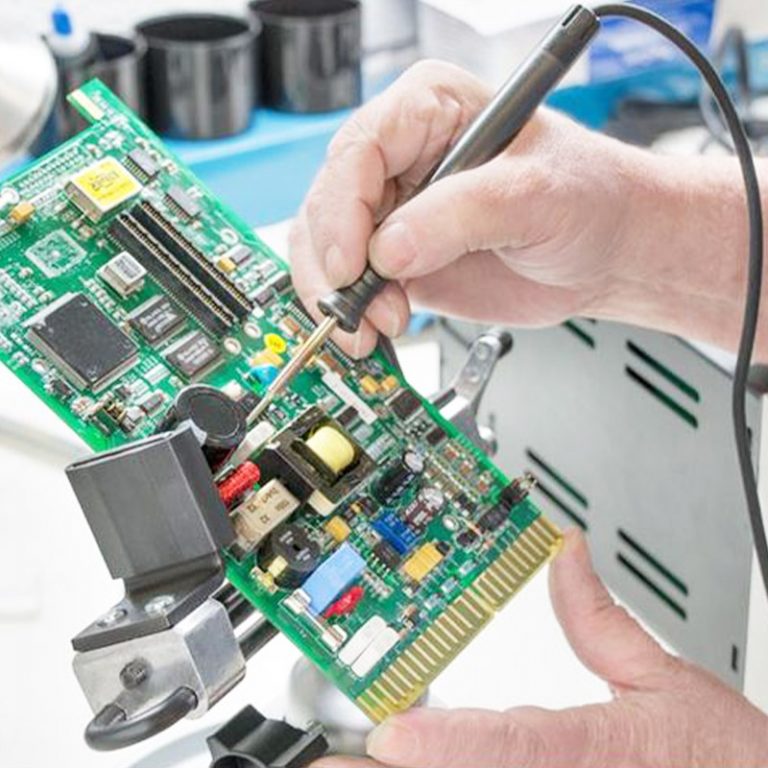

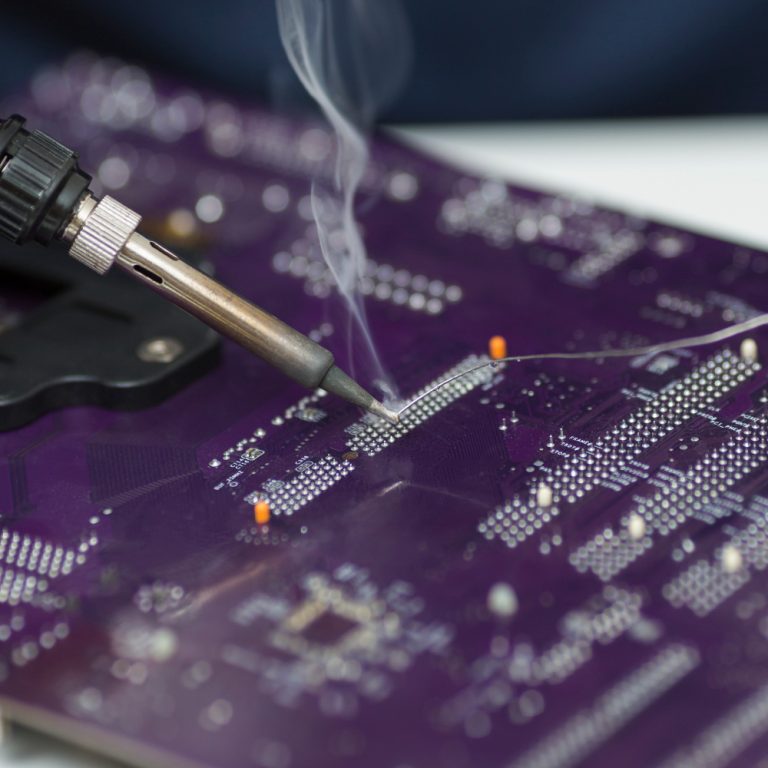

PCB repair typically involves a meticulous process that includes:

- Diagnosis: Technicians use specialized equipment to identify the root cause of the PCB’s malfunction. This may involve testing individual components, examining the board for damage, or using X-ray or infrared inspection techniques.

- Component replacement: Once the faulty components are identified, they are carefully removed and replaced with new, compatible parts.

- Trace repair: If traces on the PCB are damaged, they can be repaired using various methods, such as laser welding or the application of conductive epoxy.

- Testing: After repairs are completed, the PCB is thoroughly tested to ensure that it is functioning properly and that there are no residual issues.

CNC Controller Repair: Ensuring Precision

CNC controllers are crucial for controlling the movements of machine tools, such as lathes, mills, and routers. When a CNC controller malfunctions, it can lead to inaccurate machining, decreased productivity, and potential damage to the machine or workpiece.

Common issues with CNC controllers include:

- Hardware failures: Components like power supplies, microprocessors, and I/O modules can fail due to various reasons.

- Software glitches: Software errors or corrupted data can cause CNC controllers to malfunction.

- Communication problems: Issues with communication between the controller and other components can lead to operational problems.

CNC controller repair often involves:

- Troubleshooting: Technicians use diagnostic tools to identify the specific cause of the malfunction. This may involve checking hardware components, examining software logs, or testing communication connections.

- Component replacement: Faulty hardware components are replaced with new, compatible parts.

- Software updates: If necessary, the CNC controller’s software may need to be updated or reinstalled to address software-related issues.

- Calibration: After repairs are completed, the CNC controller may need to be recalibrated to ensure accurate positioning and movement.

Preventive Maintenance: Prolonging Component Lifespan

Regular preventive maintenance can help prolong the lifespan of PCBs and CNC controllers and reduce the frequency of repairs. Some preventive maintenance measures include:

- Regular inspections: Conduct periodic inspections to identify potential problems before they escalate.

- Cleaning: Keep components clean and free of contaminants to prevent corrosion and other damage.

- Temperature control: Ensure that components are operating within their recommended temperature range to prevent overheating.

- Power protection: Use surge protectors and uninterruptible power supplies (UPS) to protect components from electrical surges and power outages.

- Software updates: Keep CNC controller software up-to-date to address security vulnerabilities and improve performance.

By understanding the common issues, repair processes, and preventive maintenance techniques associated with PCB and CNC controller repair, businesses can minimize downtime, reduce costs, and ensure the reliable operation of their critical equipment.