In the modern industrial landscape, ensuring the efficient operation of servo motors and variable frequency drives (VFDs) is crucial. Both components play a vital role in the smooth functioning of machinery and equipment. This comprehensive guide delves into the importance, processes, and benefits of professional servo motor repair and VFD repair service.

Understanding Servo Motors and VFDs

Servo motors are widely used in applications requiring precise control of angular or linear position, velocity, and acceleration. They are essential in robotics, CNC machinery, and other automated systems.

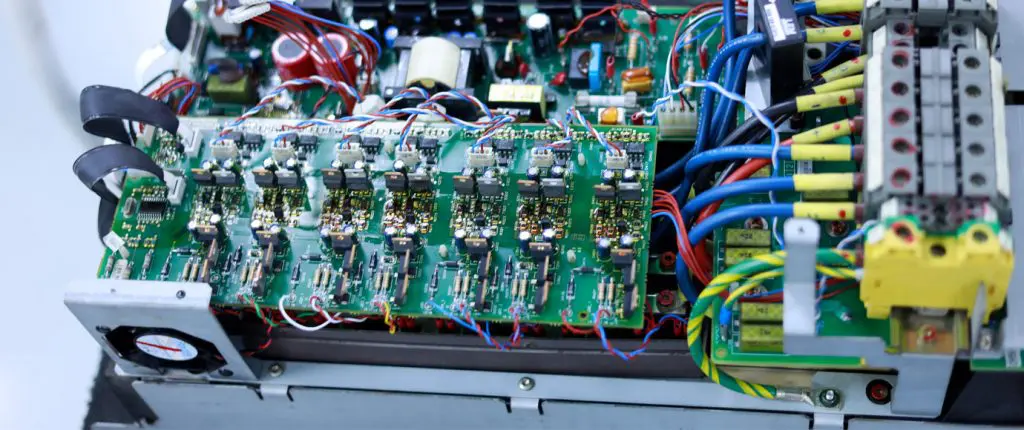

Variable Frequency Drives (VFDs), on the other hand, are used to control the speed and torque of electric motors by varying the frequency and voltage of their power supply. VFDs are crucial for energy savings and process control in industries like HVAC, manufacturing, and water treatment.

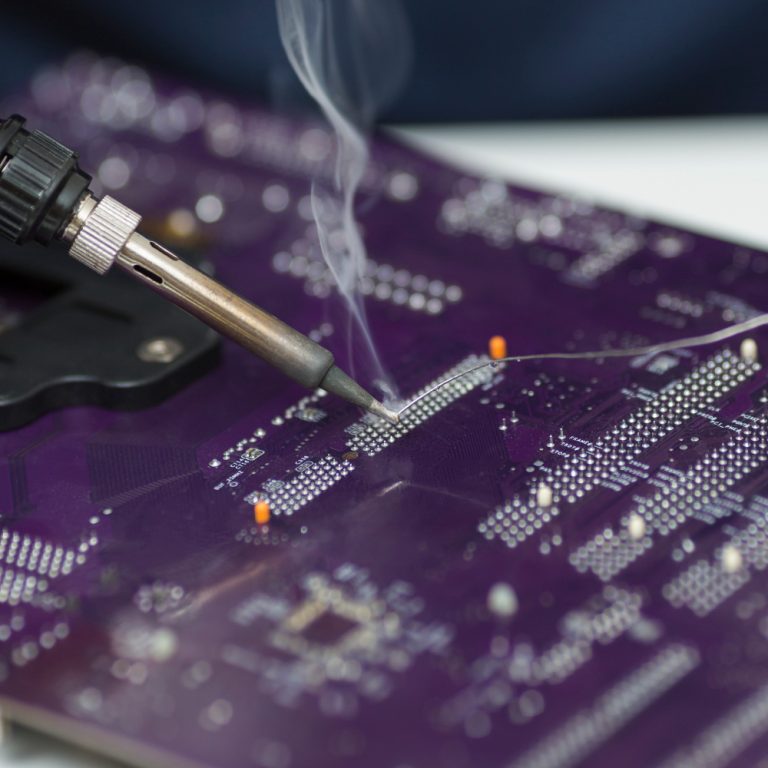

Importance of Regular Maintenance

Regular maintenance of servo motors and VFDs is vital to avoid unexpected breakdowns and ensure the longevity of these components. Regular inspections and timely repairs can prevent costly downtime and maintain the efficiency of your operations.

Common Issues and Solutions

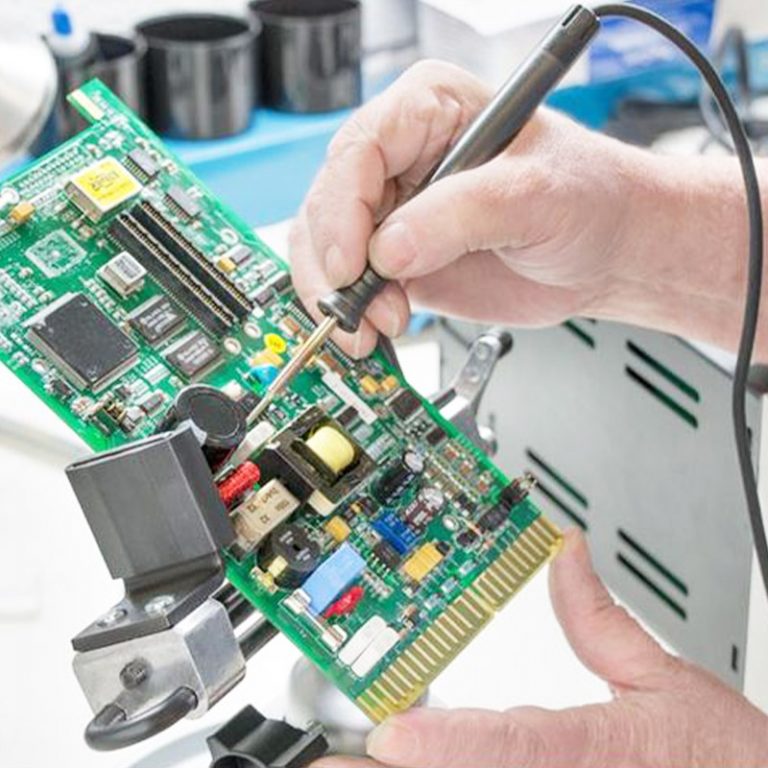

Servo Motor Repair:

- Worn Bearings: Bearings can wear out over time, leading to increased friction and heat. Replacing them is essential to maintain smooth operation.

- Electrical Faults: Issues such as short circuits or winding failures need expert diagnosis and repair.

- Encoder Problems: Encoders can fail or become misaligned, affecting the precision of the motor. Calibration or replacement might be necessary.

VFD Repair Service:

- Overheating: VFDs can overheat due to poor ventilation or excessive load. Proper cooling and load management are crucial.

- Electrical Component Failure: Capacitors, IGBTs, and other components may fail and need replacement.

- Programming Issues: Incorrect settings can lead to operational issues. Proper programming and configuration are essential.

Choosing the Right Repair Service

Selecting a reliable repair service provider is key to ensuring high-quality repairs. Look for experienced technicians, quick turnaround times, and comprehensive service offerings.

Benefits of Professional Repair Services

- Expertise and Knowledge: Trained professionals have the expertise to diagnose and fix issues accurately.

- Minimized Downtime: Quick and efficient repairs minimize production downtime, saving you time and money.

- Extended Equipment Life: Regular maintenance and timely repairs extend the lifespan of your servo motors and VFDs.

Conclusion

Maintaining the health of your servo motors and VFDs through professional repair services is essential for uninterrupted operations and efficiency. Whether you are dealing with a minor issue or a major breakdown, expert servo motor repair and VFD repair service can help you get back on track swiftly. Invest in regular maintenance and trust skilled technicians to keep your machinery running smoothly.