Constrained by the consistent pressure on benefit improvement, makers persistently hope to put resources into solutions that will assist them to increase their efficiency with less resources. That is where industrial automation goes about as an empowering influence to expand dependability and effectiveness, subsequently further developing return of investment (ROI).

Industrial automation upgrades building rate and quality by consolidating inventive and coordinated innovations, in this way diminishing expenses related with the building cycle. It makes automation one stride further by supplanting human work with PC programing and automation gadgets and hence accomplishing an exhibition better than manual activity.

Utilising gadgets like programmable logic controllers (PLCs), modern PCs (PCs) and programmable automation controllers (PACs), automation solutions smooth out modern cycles without requiring human mediation. A study by McKinsey Global Institute gauges that automation could raise worldwide efficiency by as much as 1.4 percent every year. In addition, all occupations have a fractional automation potential as a critical piece of their activities can be computerised.

Accenture estimates the capability of mechanisation gadgets to twofold the gross worth added (GVA) across 12 created economies by 2035, with work efficiency expanding up to 40%. Every one of the above realities propose that automation as an industry has enormous development potential.

An open door to Market

Worldwide, the automation market is supposed to observe fast development in the next few decades. A portion of the elements expanding the development of the automation market incorporate interest for functional productivity, innovation headway, system integration and progression in M2M communication innovation.

Essentially, the automation market in India has been developing altogether throughout the past ten years because of the rising requirement for dependable and savvy methods of creation. As per a report distributed by Ken Research, the Indian modern automation industry is supposed to reach 200 billion by 2023 with development driven by fast reception of present day innovation upheld by cost-saving highlights. The interest for factory automation in India is expected to flood with expansion in homegrown assembling and accentuation on expanded process proficiency.

Presentation of computerization in the Indian economy has brought about better items, quicker and more proficient creation (in this way diminishing waste) and mishaps minimisation on the creation floors.

Market drivers

With increasing expense of creation in China and reinforcing of Yuan against dollar, financial backers are seeing substitute assembling objections. Electronic companies in Dubai are expecting to turn into the favoured assembling objective for worldwide players. Notwithstanding, for that, it necessities to zero in on quality creation (zero imperfection) and climate friendly assembling (zero impact). Both are conceivable just with a legitimate understanding and utilisation of industrial automation.

With significant speculations expected in the UAE assembling area, the interest for processing plant automation arrangements in the nation is expected to ascend over the course of the following five years.

As indicated by a TechSci Research report, industrial facility automation arrangements are seeing a developing interest from car center points. Different areas driving the interest incorporate oil and gas, pharmaceuticals, food processing, engineering components, defence manufacturing and, of course, infrastructure.

Market difficulties for industrial automation

Automation isn’t a peculiarity that happens all of a sudden — it requires a very long time for the economy to change and develop with the developing innovation. Nonetheless, development of automation from help to full reception is probably going to require quite a few years relying upon a few elements given beneath.

Labour supply

The interest and supply of specialists for electronic repair directly conclude which activities should be automated. Nations with higher wages, may utilize automation sooner than nations with lower compensation. UAE as an industrial nation actually experiences the presence of skilled labor in the automation area. If there is no skilled personnel, it is quite challenging.

Enormous ventures

Automation requires a lot of capital spending as it includes establishment of equipment, for example, automation with enormous degrees of workings, gadgets with tangible insight capability and wheels that permit versatility. This prompts colossal introductory expenses. Nonetheless, costs decline after some time, making automation more aggressive with human work.

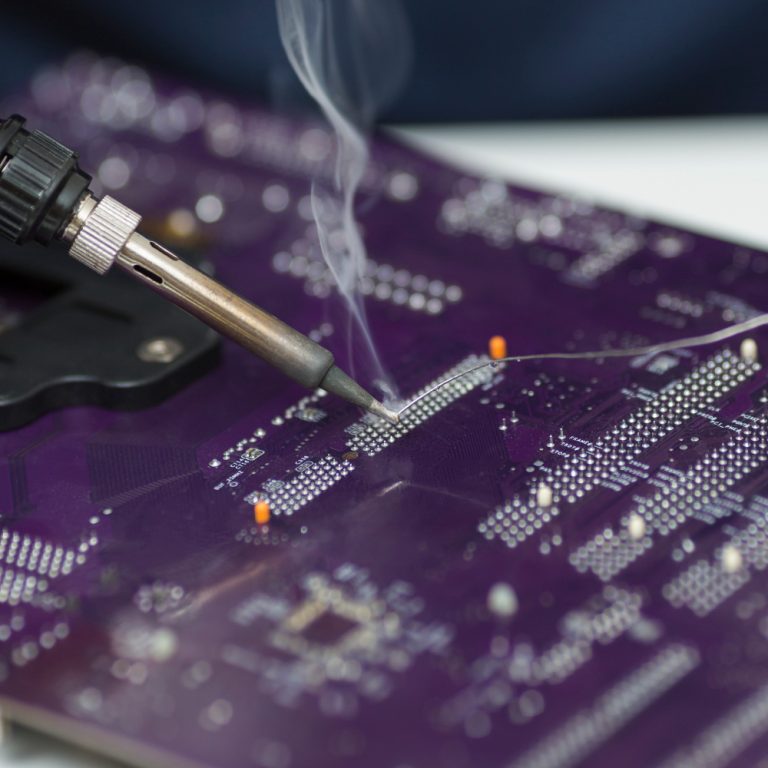

Automation gadgets frequently require persistent alterations and upkeep to meet the steadily changing usefulness of systems. As systems become further developed, programming refreshes are required. Creating and sending these gadgets requires great interest in the years to come. Consequently it is urgent to convey a system that is sufficiently adaptable to develop and adjust.

Innovation

Automation can be sent exclusively in regions that are mechanically cutting-edge enough. Machines are expected to arrive at a specific degree of skill to do automated activities.

Admittance to information

For organizations that are hoping to apply automation to quite a few regions, information access will be probably the greatest test. Digital reasoning and automation gadgets require many multiple times more data than people to figure out ideas or perceive highlights. In some cases, little organizations and new companies might not have adequate information assortment offices to run digital processes.

Moving forward: what can be expected?

Reality of Adopting Technologies and Trends states that the following modern unrest will be founded on unification of the data among members in the whole worth chain — from item origin to configuration, assembling, administrations and even restoration. The report notes, “It will change the assembling processes in a state of harmony with the speed of progress in client needs — which suggests making the manufacturing cycle adaptable without taking overabundance time.”

Advanced industrialization will develop in a with these market trends. As a matter of fact, modern automation is in front of most different ventures in status for the Internet of Things (IoT) and, all the more explicitly, the Industrial Internet of Things (IIoT) or Industry 4.0, which is one of the essential megatrends affecting the worldwide mechanization market.

A new report by HIS Technology estimates modern automation to make up a greater part of the IoT by 2025, with Internet convention (IP)- addressable gadgets as the key empowering influence. The report expresses that modern automation represented the greater part of the introduced base for all Internet-associated gadgets in 2012. The area will develop at 36.3 percent every year to represent almost three-fourths of all associated gadgets by 2025.

Avoid Downtime! Get Fast & Reliable Nidec Drive Repairs in Dubai

Nidec drives are essential components in modern industrial automation, ensuring smooth and efficient motor control. However, like any electronic equipment, they are prone to issues