Understanding AC Drives

AC drives, also known as variable frequency drives (VFDs), are essential components in modern industrial applications. They regulate the speed and torque of AC motors, offering precise control and energy efficiency. However, like any electronic equipment, AC drives can malfunction due to various factors. When faced with an AC drive failure, seeking professional repair services is crucial to ensure optimal performance and minimize downtime.

Common AC Drive Issues

- Overheating: Excessive heat can damage components and shorten the lifespan of an AC drive.

- Power Supply Problems: Fluctuations or surges in power supply can lead to drive failure.

- Contamination: Dust, dirt, or other contaminants can interfere with the drive’s internal circuitry.

- Hardware Failures: Components like transistors, capacitors, or control boards may experience physical damage.

- Software Glitches: Programming errors or software corruption can cause erratic behavior.

Why Choose Professional AC Drive Repair Services

- Expertise and Experience: Repair technicians are trained to diagnose and address a wide range of AC drive issues.

- Diagnostic Tools: They employ advanced diagnostic equipment to pinpoint the root cause of problems accurately.

- Genuine Parts: Professional repair services use original or compatible parts to ensure quality and longevity.

- Timely Repairs: Efficient repair processes minimize downtime, reducing operational losses.

- Preventive Maintenance: Regular maintenance can help prevent future failures and extend the life of your AC drive.

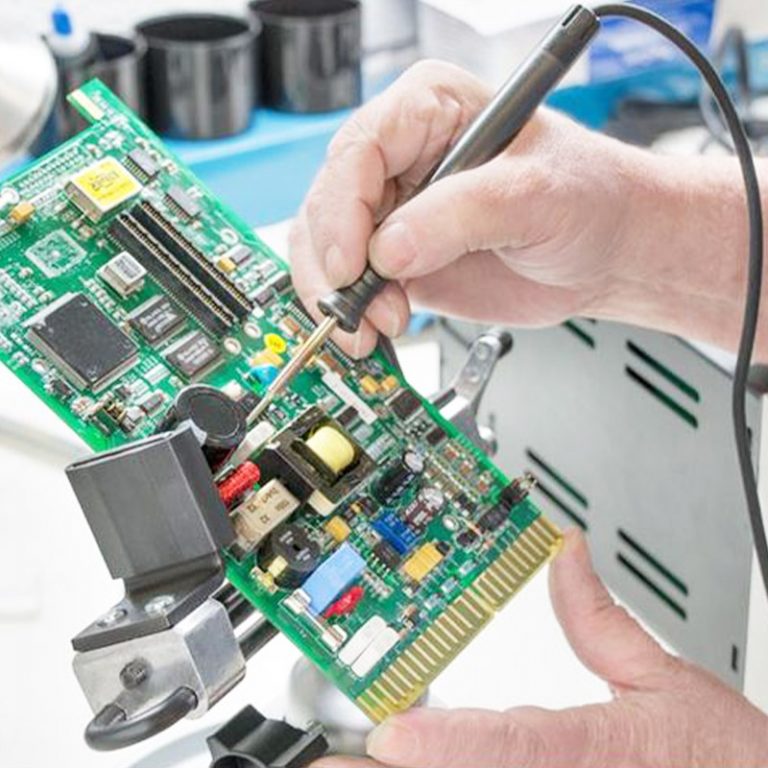

AC Drive Repair Process

- Initial Assessment: The repair service will evaluate the drive’s condition and gather information about the symptoms.

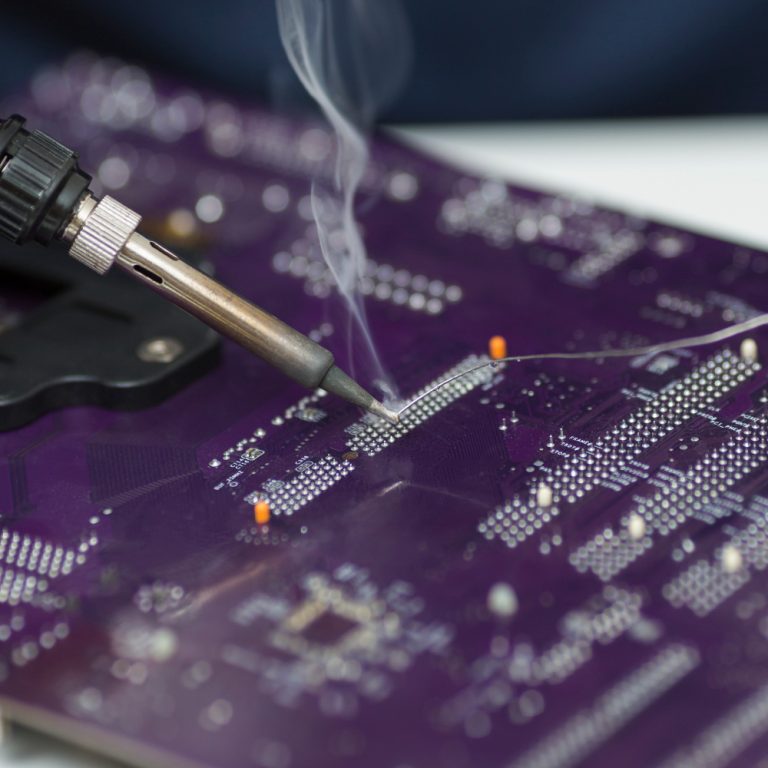

- Troubleshooting: Technicians use diagnostic tools to identify the faulty components or software issues.

- Repair or Replacement: Damaged parts may be repaired or replaced with compatible alternatives.

- Testing and Calibration: The repaired drive is thoroughly tested to ensure proper functionality and is calibrated to meet specific requirements.

- Quality Assurance: A final inspection is conducted to verify that the drive is operating optimally before it is returned.

Preventive Measures for AC Drive Health

- Regular Maintenance: Conduct routine inspections, cleanings, and software updates.

- Environmental Considerations: Protect the drive from extreme temperatures, humidity, and contaminants.

- Power Quality: Use surge protectors or uninterruptible power supplies to stabilize the power supply.

- Proper Installation: Ensure the drive is installed correctly and securely.

Selecting the Right AC Drive Repair Service

When choosing an AC drive repair service, consider the following factors:

- Experience: Look for a company with a proven track record in AC drive repairs.

- Certifications: Check if the service provider has relevant certifications or accreditations.

- Customer Reviews: Read testimonials from previous customers to gauge their satisfaction.

- Response Time: Ensure they can provide timely repairs to minimize downtime.

- Warranty or Guarantee: Inquire about any warranties or guarantees offered on repairs.

Conclusion

AC drives are critical components in many industrial applications, and their proper functioning is essential for efficient operations. When faced with an AC drive failure, seeking professional repair services is the most reliable way to restore functionality and prevent further damage. By understanding common AC drive issues, the benefits of professional repairs, and preventive maintenance practices, you can ensure the optimal performance and longevity of your AC drives.