Variable Frequency Drives (VFDs) are essential components in many industrial applications, providing precise control over motor speed and torque. When a VFD malfunctions, it can disrupt operations and lead to costly downtime. That’s where reliable VFD repair services come into play.

Understanding VFD Repair Services

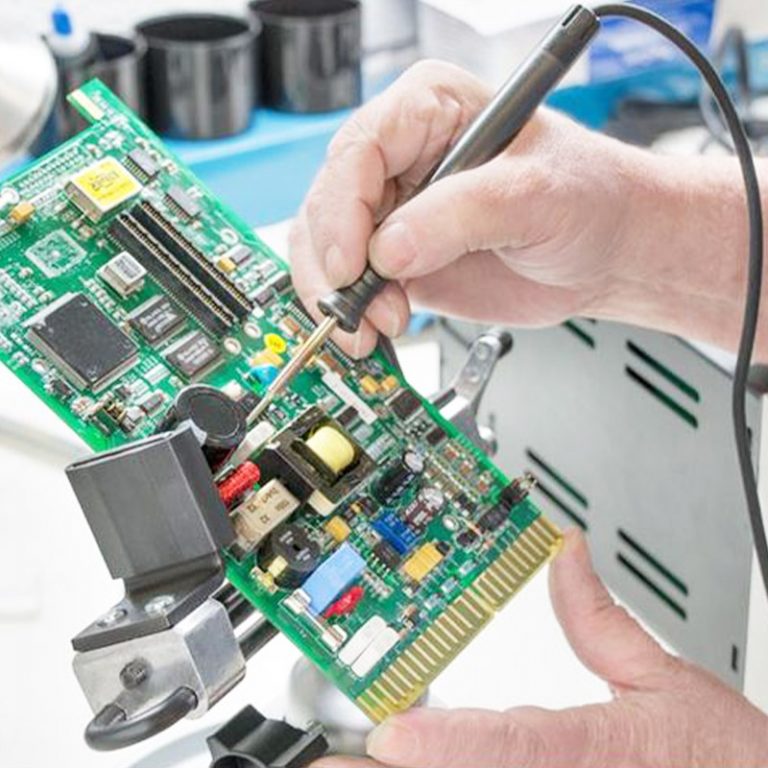

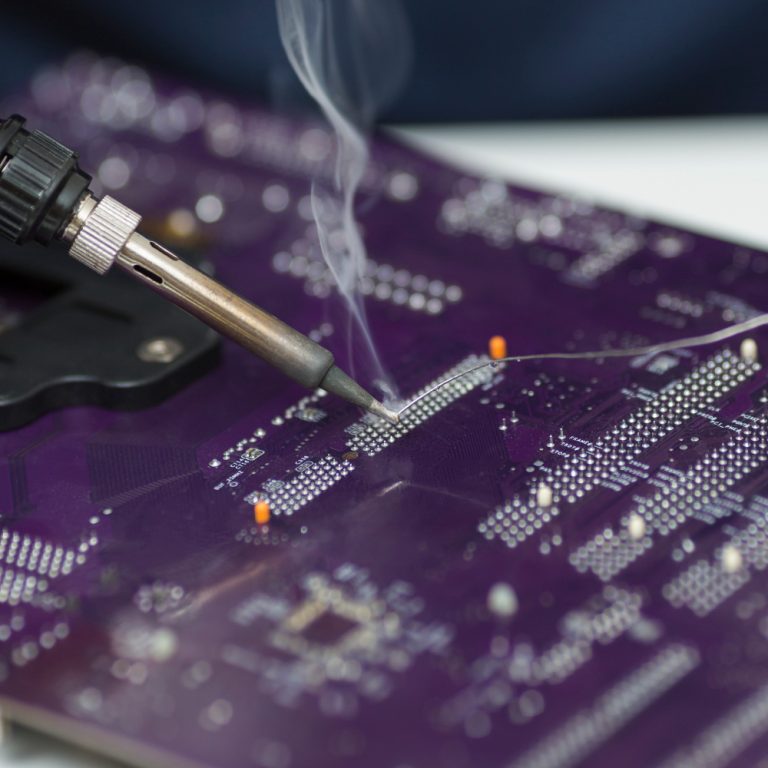

VFD repair services involve diagnosing, troubleshooting, and repairing faulty VFDs to restore their functionality. Experienced technicians use specialized tools and techniques to identify the root cause of the problem and implement effective solutions.

Common VFD Issues and Repairs

- Overheating: Excessive heat can damage VFD components. Technicians may inspect cooling fans, heat sinks, and thermal sensors to identify and address overheating issues.

- Power Supply Problems: Faulty power supplies can prevent VFDs from operating correctly. Repair services often involve testing and replacing defective power supply components.

- Control Circuit Failures: Malfunctions in the control circuit can disrupt VFD operation. Technicians may need to examine circuit boards, transistors, and other electronic components to identify and repair the issue.

- Sensor Issues: Faulty sensors can lead to inaccurate speed or torque control. Repair services may involve calibrating or replacing defective sensors.

- Contamination: Dust, dirt, or other contaminants can accumulate inside VFDs and cause damage. Regular cleaning and maintenance can help prevent contamination-related problems.

The Importance of Professional VFD Repair

Attempting to repair a VFD yourself can be risky and may lead to further damage. Professional VFD repair services offer several advantages:

- Expertise: Technicians have the knowledge and experience to diagnose and repair complex VFD issues efficiently.

- Specialized Tools: They use specialized equipment to accurately test and measure VFD components.

- Quality Parts: Professional repair services typically use high-quality replacement parts to ensure long-lasting performance.

- Warranty: Many repair services offer warranties on their work, providing added peace of mind.

Choosing the Right VFD Repair Service

When selecting a VFD repair service, consider the following factors:

- Experience: Look for a company with a proven track record in VFD repair.

- Certifications: Check if technicians have relevant certifications or qualifications.

- Customer Reviews: Read customer testimonials to gauge the quality of service and customer satisfaction.

- Turnaround Time: Inquire about the typical turnaround time for repairs to minimize downtime.

- Emergency Services: If your VFD is critical to operations, ensure the repair service offers emergency repair options.

By investing in reliable VFD repair services, you can minimize downtime, optimize equipment performance, and protect your valuable assets. Regular maintenance and timely repairs are essential for keeping your VFDs running smoothly and efficiently.