Servo motors, precision components that offer precise control and positioning, are indispensable in various industries. However, like any mechanical or electrical device, they can experience malfunctions. When a servo motor fails, it can disrupt operations, leading to costly downtime. Understanding common issues and effective repair techniques is crucial for maintaining efficient and reliable systems.

Common Servo Motor Problems

- Mechanical Failures:

- Gearbox wear and tear

- Bearing damage

- Shaft misalignment

- Foreign object intrusion

- Electrical Issues:

- Controller malfunctions

- Encoder problems

- Power supply irregularities

- Wiring faults

- Thermal Concerns:

- Overheating due to excessive load or poor ventilation

- Undercooling leading to performance degradation

Troubleshooting Tips

- Visual Inspection:

- Check for any visible signs of damage, such as cracks, burns, or loose connections.

- Look for signs of overheating, like discoloration or warping.

- Noise Analysis:

- Listen for unusual noises, such as grinding, squealing, or clicking sounds. These can indicate mechanical problems.

- Movement Assessment:

- Observe the servo motor’s movement for any irregularities, such as jerky motions or failure to reach the desired position.

- Error Code Checks:

- Consult the servo motor’s user manual to understand the meaning of any error codes displayed.

- Diagnostic Tools:

- Use specialized diagnostic tools to measure voltage, current, and other electrical parameters.

- Check encoder signals and controller communication.

Repair Techniques

- Gearbox Replacement:

- If the gearbox is damaged, it may need to be replaced. This often requires disassembling the servo motor and replacing the entire gearbox assembly.

- Bearing Replacement:

- Worn or damaged bearings can cause noise, vibration, and reduced performance. They can be replaced by disassembling the servo motor and carefully removing and installing new bearings.

- Shaft Alignment:

- Misaligned shafts can lead to increased wear and tear, reduced efficiency, and even motor failure. Ensure proper alignment using alignment tools and following manufacturer guidelines.

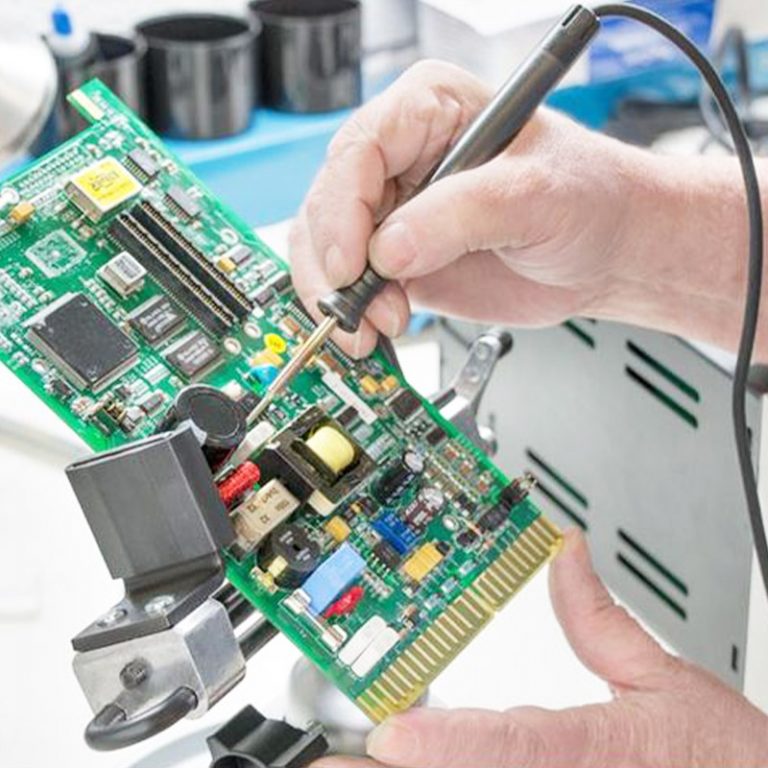

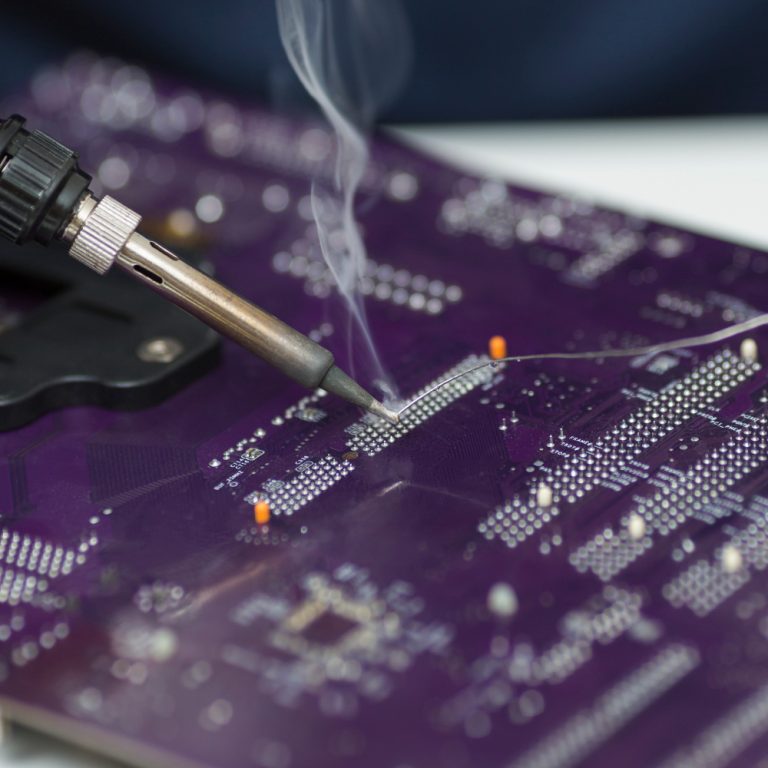

- Electrical Component Repair:

- If electrical components like the controller, encoder, or power supply are faulty, they may need to be repaired or replaced. Consult a qualified technician for complex electrical repairs.

- Thermal Management:

- Ensure adequate ventilation to prevent overheating. Consider using heat sinks or fans to improve cooling.

- Check for any obstructions that may be blocking airflow.

Preventive Maintenance

- Regular Inspections:

- Conduct routine inspections to identify potential problems early on.

- Check for signs of wear, damage, or contamination.

- Cleaning and Lubrication:

- Clean the servo motor’s external surfaces and moving parts to remove dirt and debris.

- Apply appropriate lubricants to bearings and other moving components.

- Load Matching:

- Ensure that the servo motor is rated for the intended load to prevent overloading and overheating.

- Environmental Considerations:

- Protect the servo motor from harsh environments, such as extreme temperatures, moisture, or corrosive substances.

By understanding common servo motor repairs, troubleshooting techniques, and preventive maintenance practices, you can significantly improve the reliability and longevity of your equipment. When repairs are necessary, seeking professional assistance from experienced technicians can ensure that the servo motor is restored to its optimal performance.